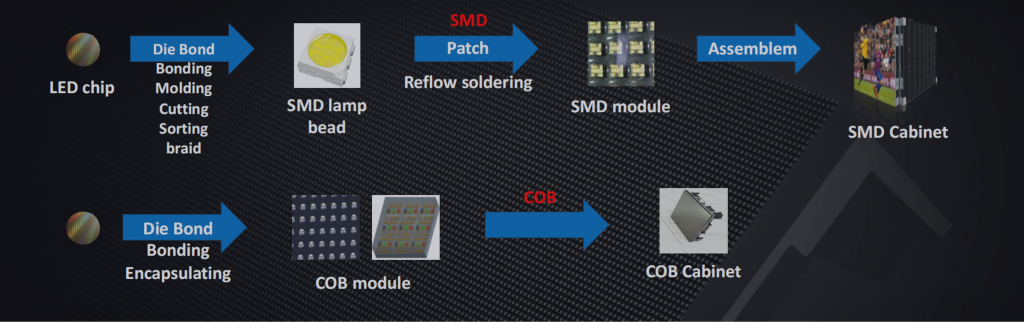

About the definition of Micro type full flip chip common cathode COB display panel:

- MICRO type: MICRO pixel pitch

- Full flipchip: R/G/B all color Flipchipdies

- Common cathode: energy saving and cool temperature in operation

- COB panel:chip on board encapsluation

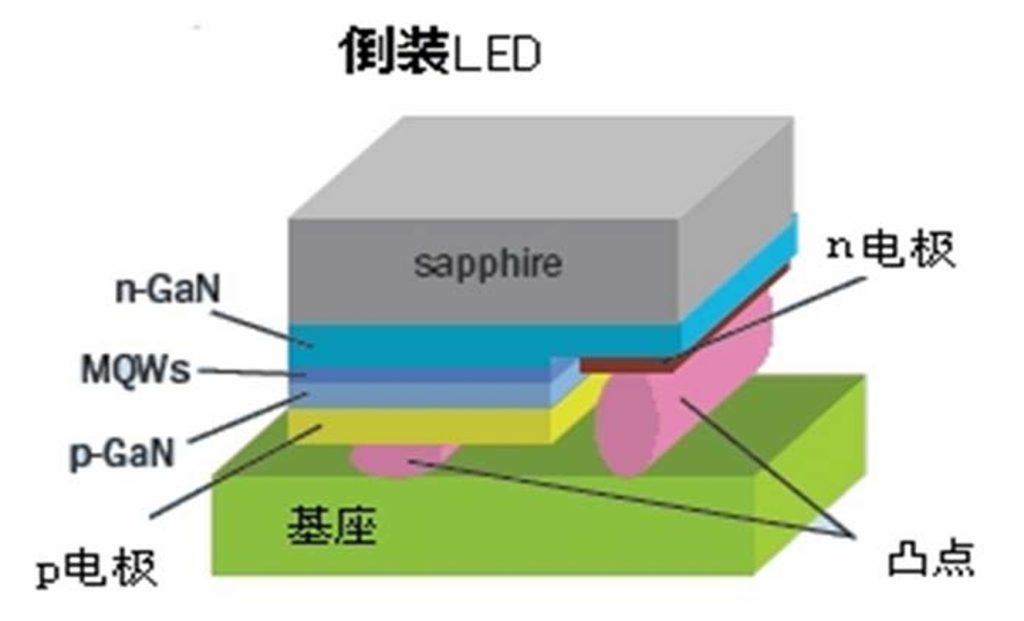

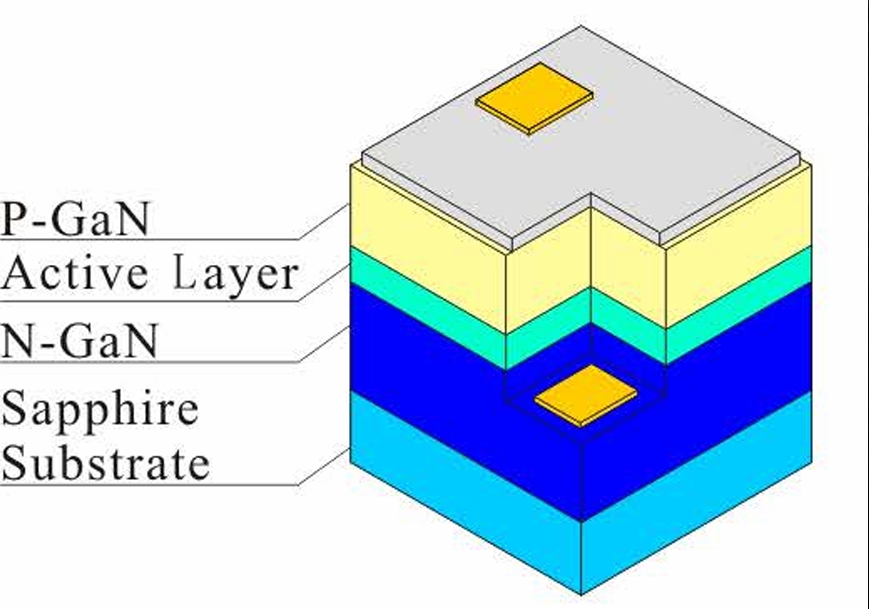

Introduction Of Flip Chip Technology

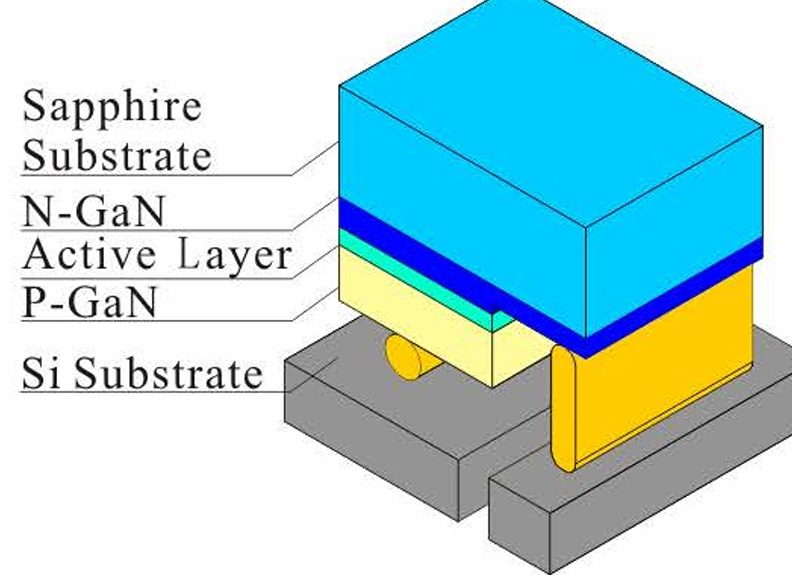

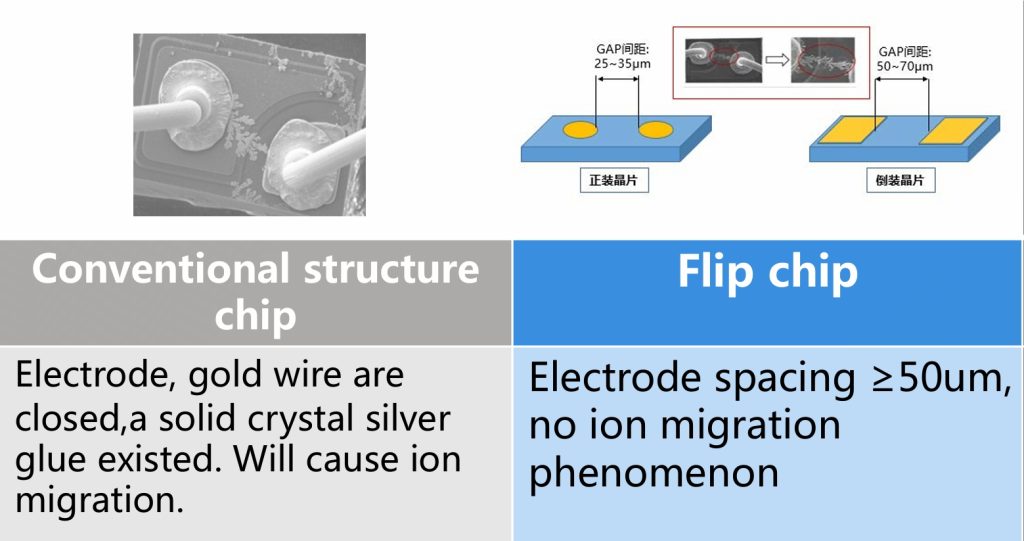

The reason we named “Flip chip” is basing on the comparison with the conventional Wire Bonding and Ball Bonding technology. Conventionally, by connecting the wafer on substrate with metal wire bonding, the circuit design for P&N poles is facing upward. But the circuit design on the Flip chip is facing downward, which is equivalent to turning the former over, so it is called “Flip chip”, and the corresponding encapsulation process is called “Flip chip process.” Comparing with the conventional Horizontal Structure chip (both P/N electrodes up) packaging technology, Flip chip encapsulation reduces the gold wire bonding process, and leaves only the chip and solder paste together with phosphors.

Comparison Between Flip Chip And Conventional Structure Chip

1.Stronger- Compare to conventional welding line LED,flip chip process use stronger chip soldering materials,the tolerable thrust is high 100 times than traditional bolding LED.

2.Reliability- The solder paste used in Flip chip process has a better capacity on heat dissipation than silver paster of traditional LEDs structure.

3.Efficient- Flip chip fixed crystal process only takes 3-5 mins, compare to conventional bolding line LED, saved more than 20 times time ,greatly improve production efficiency.

4.Repairable- The defective flip chip is able to repair because it’s simpler process,unlike tradiontal complex structure LEDs is hard to repair.

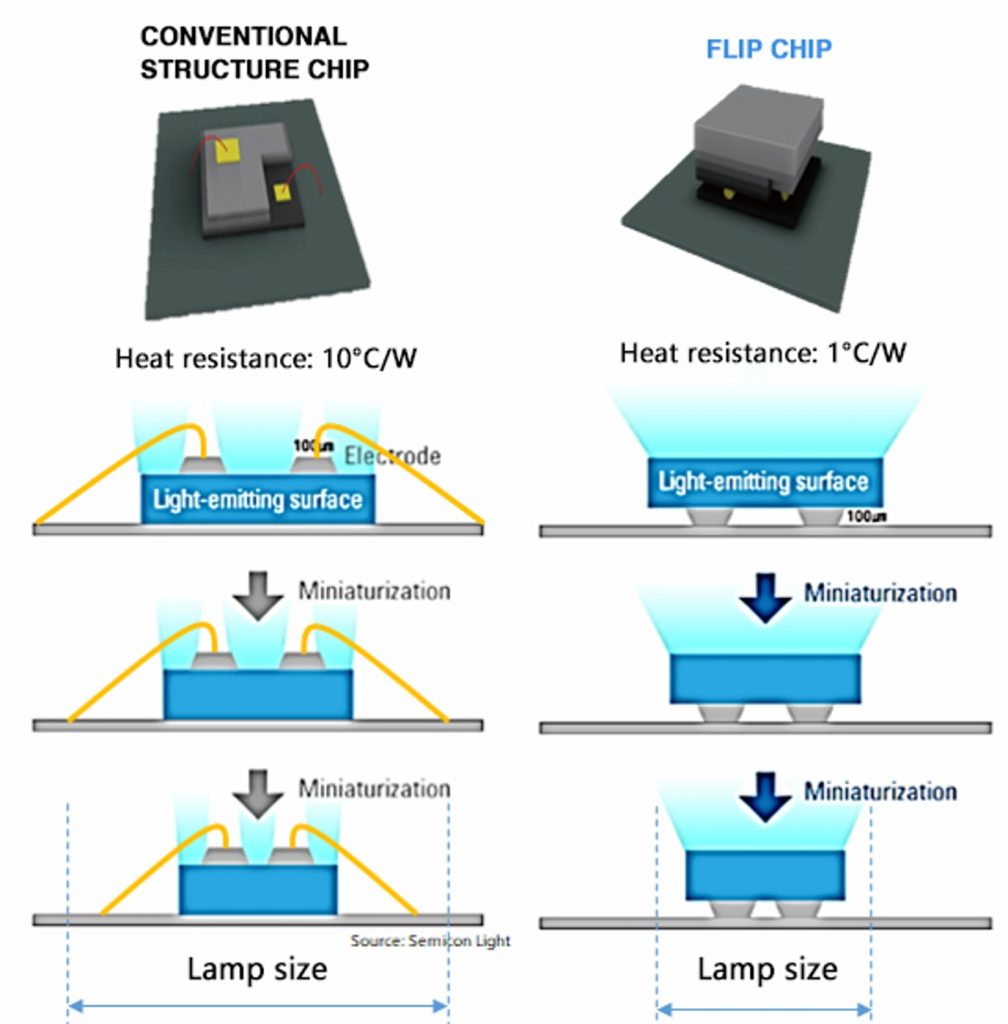

When the chip is miniaturized

- For the conventional structure chip, the shading ratio and thermal resistance of the electrode raise,the light efficiency is getting low, and the life is gettingshort. The wire distance limits the fine pitch design.

- Flip chip, no cover on the light emitting surface, the electrode is flat on the padand withgood heat dissipation, high light efficiencyandlong life.Nobonding wire and is suitable for fine pitch design.

| Cost | Manufacturer complexity | Yield Rate | Reliability | Heat dissipation | Inside ESD protection | |

| Conventional Horizontal Structure chip | Low | Easy | Low | Normal | Normal | No |

| Flip Chip | Normal | Complex(by now) | High | Excellent | Excellent | >6000V (HKB), easy to realize |